Print Sleeves

Mounting

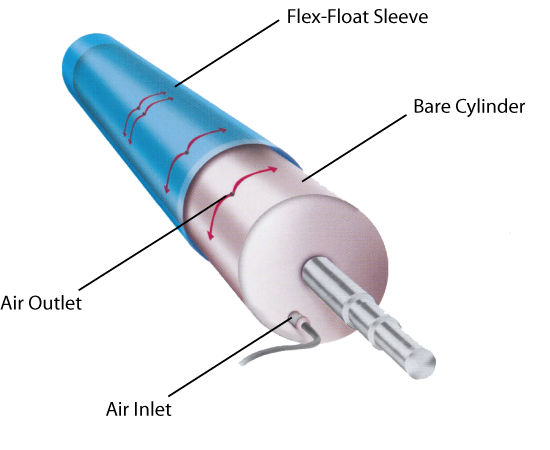

To mount your Flex-Float sleeve onto the cylinder simply apply compressed air at

approximately 50 PSI through the air inlet, enabling you to “float” the sleeve into position. Fingertip guiding is all that is required to fine-tune the final position. Once air pressure is removed, the sleeve will become vacuum-tight to the bare cylinder for mounting and /or the actual press run.

Ease of Handling

Flex-Float sleeves are constructed of tough polyester material, plus they are feather light to handle.

Re-Runs

The Flex-Float sleeve becomes the carrier for the mounted plates. Thus -, re-runs are easy because the plates are stored in register on the sleeves, saving on remounting and re-registering costs.

Storing

We ship your sleeves in 1/8” thick fiber tubes. These tubes can also be utilized for storing the mounted Flex-Float sleeve. A label is placed on the lid of the tube for easy identification. Storing the plate-mounted sleeve in these tubes will protect the plates from accidental bruising while keeping them free of dust and ozone.

How to order

Flex-Float sleeves are available in any specified BCD (Bare Cylinder Diameter) from approximately 2” to 15” and in any face width up to 65”. Inform us of your specs and we will be happy to quote you the sleeve cost. We also provide a Platemaking, mounting, and proofing service utilizing Flex-Float sleeves

What we do

Flexi-Pharma provides image carriers for many Pharmaceutical printing applications. Blister Packaging, IV bags, and packaging labels are just a few examples.

Let us show you a secure user-friendly way to bring a higher level of Process Control into your production.